Apprentice Guide

Apprentice Guide

No need to 'add to cart', the full document is linked below. Just click to open full screen, read and download.

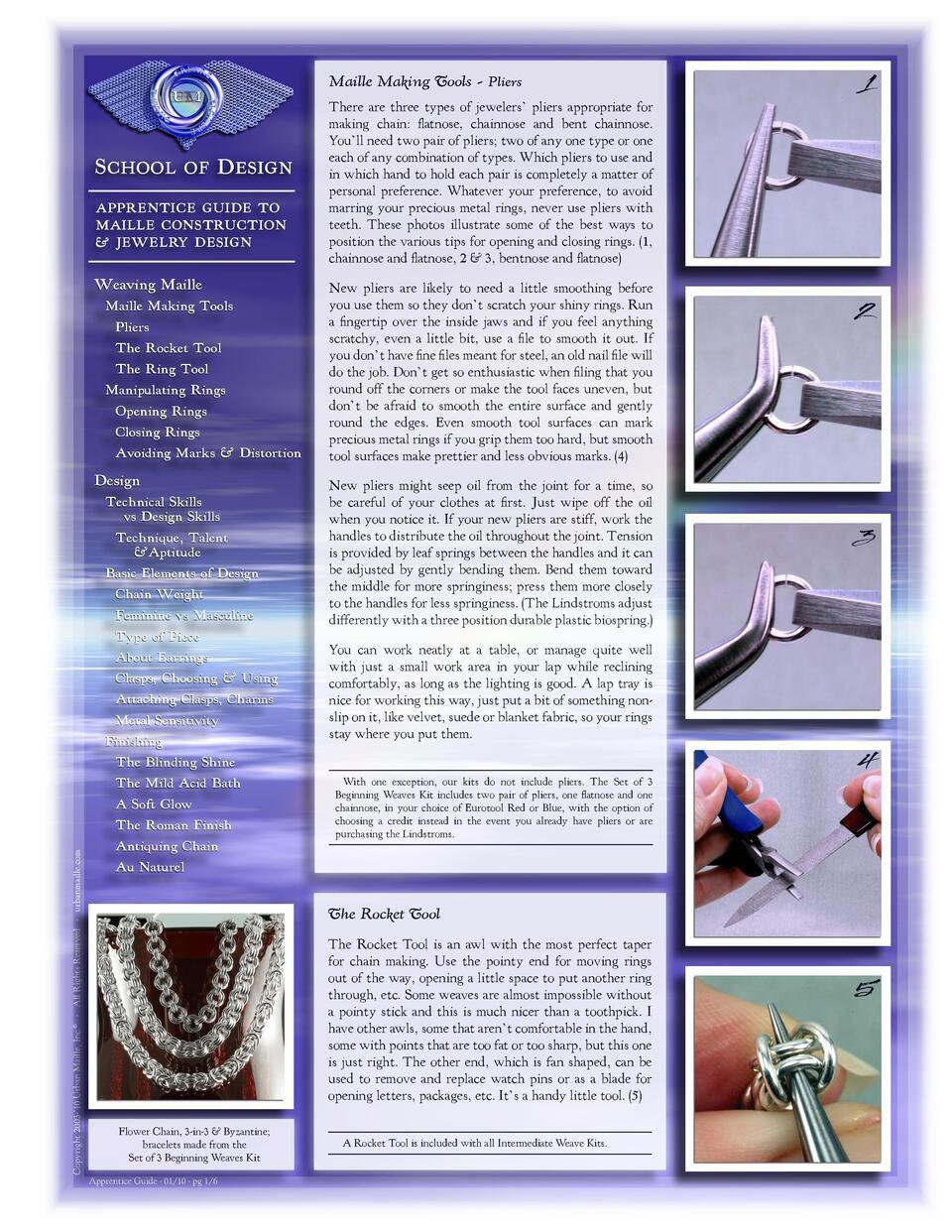

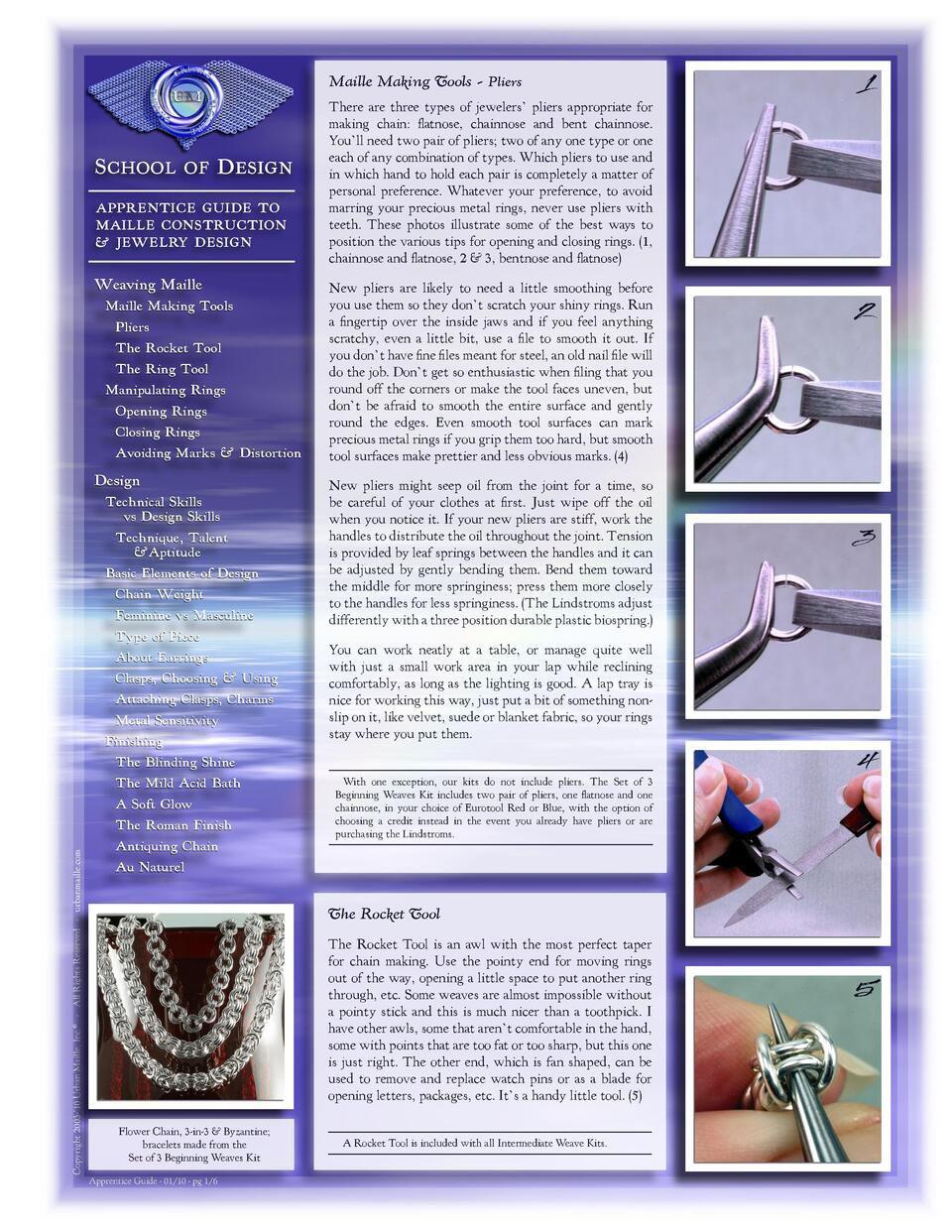

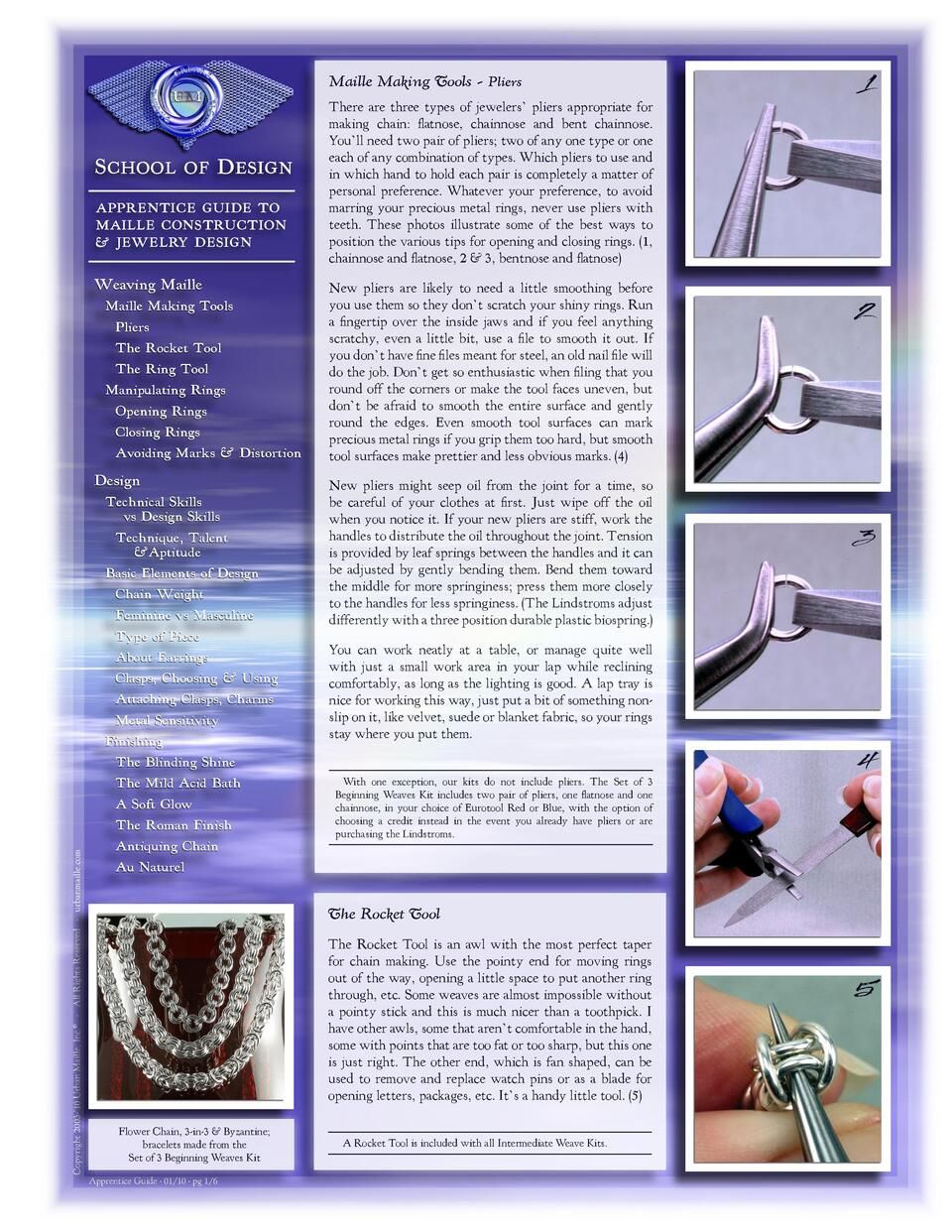

Our Apprentice Guide teaches everything you need to know to get started making beautiful chainmaille jewelry for fun and / or profit.

As with all of our work, we invite you to make and sell as many of everything as you like, but ask that you don't publish our instructions or ring sizes.

See all of our free, downloadable instructions in the

UM Library.

Regular price

$0.00 USD

Regular price

Sale price

$0.00 USD

Unit price

per

Shipping calculated at checkout.

Couldn't load pickup availability